Nondestructive Testing – The Gift of Couplers

Let’s talk about couplers and why they’re so great for testing! Everything that’s manufactured must be tested – concrete, fabric, computer chips, blenders, etc. Everything. And unfortunately, many tests are either “destructive” or “disruptive” – meaning you must break the part to test it (i.e. crushing concrete) or use the product outside of its normal purpose (i.e. blending nothing). This results in lost product, lost time, or both, which are detrimental when trying to conduct a business. Because of this, industries are always on the hunt for non-destructive and non-disruptive tests. How does this relate to couplers? They are a great tool for these tests.

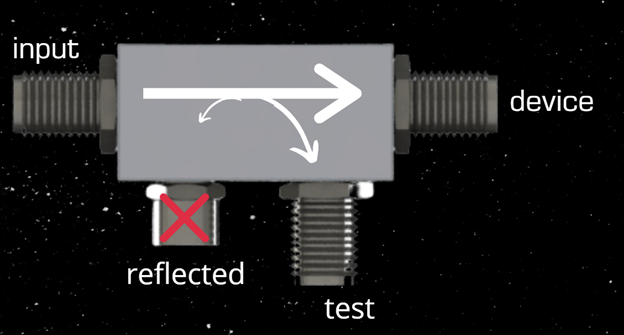

Couplers work by taking in a signal, coupling it to another line, and sending a large portion through the through port and a small portion through the coupling port. Because the portions of power are known, the small signal going through the coupling port is an indication of the total signal going through. For example, workers needing to test an amplifier before a cell tower may put a coupler in the RF line following the amplifier. Using the coupling port, test engineers can see how much power is coming through the port and back calculate the total amount of power going through the coupler. Because most of the signal is still going to the tower, this is a great non-destructive test. It is only minorly disruptive (since it takes some signal away), but allows real measurements in real time. The fourth port of the coupler is capped using a small termination to prevent any reflected signal from bouncing out of the system.

XMA makes couplers operating from .5-65GHz and up to 50W of average power. With industry leading VSWR and space-ready coupler designs, we are ready to help with nondestructive RF testing! As always, feel free to reach out if you have questions or comments.